Tilton has upgraded their popular line of OT-140 5.5” metallic clutches with the addition of lower rate diaphragm spring options. While still providing high torque capacity, the new diaphragm springs significantly reduce release loads compared to other 5.5″ racing clutches on the market. The lower release loads put less stress on engine crankshaft thrust bearings, making these clutches ideal for smaller 4-cylinder and 6-cylinder engines. In addition, a lower release load on the clutch equates to less pedal effort for the driver, allowing for easy shifting. Spring options now include White (W), Orange (ORA) and Gray (G). 5.5″ OT-140 metallic racing clutches are available in 1, 2, 3 and 4-plate configurations.

Tilton’s 5.5″ OT-III metallic racing clutches offer the low moment-of-inertia, high torque capacity and reliability necessary for the most demanding racing applications. These features have made metallic clutches the most common clutch type used in road racing and circle track racing. The included high ratio pressure plate features short release travel for quick engagement and shifting as well as a flat clamp load curve for longer wear range. 5.5″ OT-140 metallic racing clutches are not recommended for street use.

5.5″ OT-140 metallic racing clutches applications include:

- Road Racing

- Circle Track

- Open Wheel

- Formula

- Short Course Off Road

Design

The open, one-piece clutch cover design keeps operating temperatures lower and ensures high strength and minimal deflection for quick shifting.

Engineering

Chrome vanadium diaphragm springs and an engineered pressure plate geometry provide a high clamp load-to-wear ratio, low release load and quick shifting.

Materials

High-strength steel is used in both the pressure plates and the floater plates.

Toughness

.104″-thick friction disc withstands elevated temperatures while providing low inertia and excellent wear resistance.

Operation

Hardened steel thrust buttons provide smooth and durable surface for pressure and floater plates.

Testing

Every Tilton OT clutch is dynamically balanced to ensure the highest level of performance.

Quality Assurance

Each OT clutch is individually inspected for proper assembly and balance, and initialed by the quality personnel as confirmation.

1-Plate Specifications:

Weight**: 4.1 lbs/1.9 kg

M.O.I.**: 19.5 lb-in2/.0057 kg-m2

Spring Color | Torque Capacity

(lb-ft/Nm) | Release Load - New*

(lbs/daN)

| Release Load -

Max Wear*

(lbs/daN) |

White | 150/204 | 375/165 | 480/211 |

Orange | 200/272 | 510/225 | 650/286 |

Gray | 250/340 | 685/302 | 880/388 |

2-Plate Specifications:

Weight**: 5.7 lbs/2.6 kg

M.O.I.**: 29.8 lb-in2/.0087 kg-m2

Spring Color | Torque Capacity

(lb-ft/Nm) | Release Load - New*

(lbs/daN)

| Release Load -

Max Wear*

(lbs/daN) |

White | 300/408 | 375/165 | 480/211 |

Orange | 400/544 | 510/225 | 650/286 |

Gray | 500/680 | 685/302 | 880/388 |

3-Plate Specifications:

Weight**: 7.3 lbs/3.3 kg

M.O.I.**: 40.1 lb-in2/.0118 kg-m2

Spring Color | Torque Capacity

(lb-ft/Nm) | Release Load - New*

(lbs/daN)

| Release Load -

Max Wear*

(lbs/daN) |

Orange | 600/816 | 510/225 | 650/286 |

Gray | 750/1020 | 685/302 | 880/388 |

4-Plate Specifications:

Weight**: 8.9 lbs/4.0 kg

M.O.I.**: 50.1 lb-in2/.0148 kg-m2

Spring Color | Torque Capacity

(lb-ft/Nm) | Release Load - New*

(lbs/daN)

| Release Load -

Max Wear*

(lbs/daN) |

Orange | 800/1088 | 510/225 | 650/286 |

Gray | 1000/1360 | 685/302 | 880/388 |

All 5.5″ metallic clutches feature a high-ratio pressure plate.

* Values listed are typical for release bearings with the recommended 38mm contact diameter. Larger contact diameters will increase release load.

** Weight and M.O.I. include pressure plate, carbon floater plates, carbon discs and steel hub, and may vary based on your particular spline.

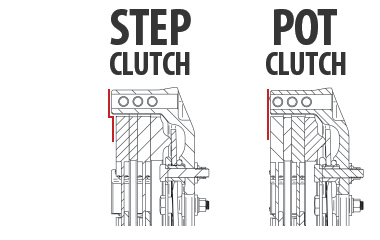

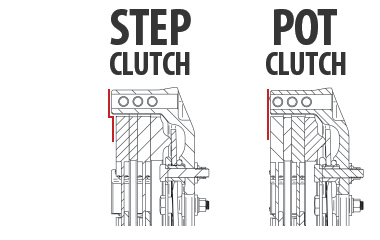

Tilton offers two different styles of every clutch configuration: one designed to be compatible with a step-type flywheel, and another for pot-type (“no-step”) flywheels. Step flywheels have a .100″ step for contact with the friction material of the clutch, so clutches made for this application will have a .100″ height difference between the bottom friction disc and the end of the clutch cover legs (the mounting points). Pot flywheels don’t have this step, so the friction disc and clutch cover legs will be flush on clutches designed for them.

Tilton uses a color system for indicating the angle and weight of the clutch spring, which has an effect on release load and torque capacity for the clutch. The exact values for each color vary depending on the type of clutch, so be sure to check the Specs tab to find exact measurements.

P65 Notice

P65 Notice