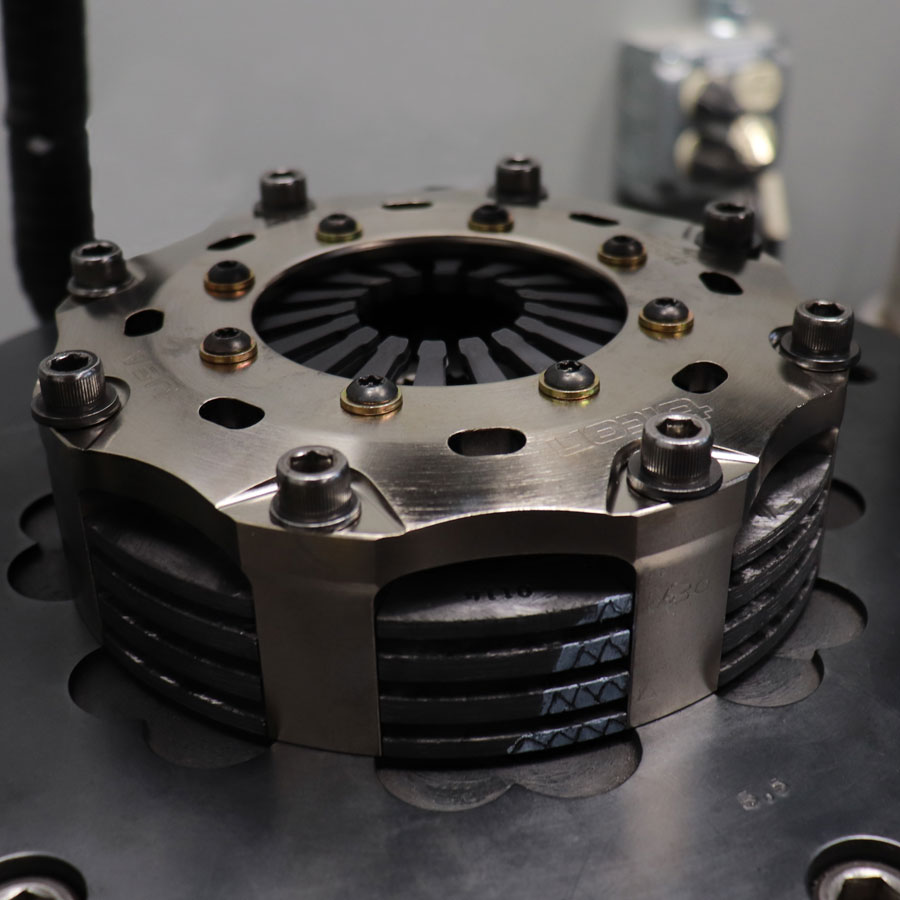

Tilton’s 5.5″ OT-III carbon racing clutches offer a unique combination of extremely low inertia, high torque capacity, high heat capacity and smooth engagement characteristics. The carbon matrix plates (driven and floater) do not warp from heat, providing consistent shifting and minimizing heat-related clutch failures. The smooth engagement characteristics of the carbon plates provide excellent drivability and reduce shifting shock to other driveline components. Through the use of additional pressure plates (shims) and periodic rebuilds, 5.5″ OT-III carbon racing clutches offer a long-life option for the serious racer. These features make Tilton’s 5.5″ carbon racing clutch ideal for the following applications:

- Road racing

- Endurance racing

- Short-course off-road

- Open-wheel/formula

Extremely Low Inertia

The moment of inertia for Tilton’s 5.5″ OT-III carbon racing clutches range from 14.6 lb-in

2 (.0043 kg-m

2) to 25.3 lb-in

2 (.0074 kg-m

2).

Lightweight

Tilton’s 5.5″ carbon clutches range in weight from 3.0 lbs (1.4 kg) to 5.2 lbs (2.3 kg).

High Torque Capacity

Tilton’s 5.5″ carbon clutches can handle 250 lb-ft (340 Nm) of torque per plate with a high-ratio pressure plate, and 300 lb-ft (408 Nm) of torque per plate with an ultra-high-ratio pressure plate.

Decades of Experience

Tilton Engineering invented the carbon/carbon racing clutch and patented the drive system in the 1980s. It was the first carbon/carbon clutch ever to win a Formula One Grand Prix (Ayrton Senna’s Lotus-Honda at the 1980 US Grand Prix in Detroit). Since then, Tilton carbon/carbon clutches have been continually refined to be the best carbon clutches on the market. They have seen multiple victories in races worldwide, from the 24 Hours of Le Mans to the Baja 1000.

Capitalizing on experience gained over the past decades, Tilton carbon clutches have evolved to become second to none in quality. Each is built using the finest materials, the latest in manufacturing processes and is held to strict quality control standards. As part of their build process, 5.5″ OT-III carbon racing clutches are rigorously tested and documented before being delivered to the customer.

Plate count | Release Load*

(lbs/daN) | Weight**

(lbs/kg) | M.O.I.**

(lb-in2/kg-m2) | Torque Capacity

(lb-ft/Nm) | Pressure

Plate

Ratio |

1-plate | 850/375 | 3.0/1.4 | 14.6/.0043 | 250/340 | High |

" | " | " | " | 300/408 | Ultra-High |

2-plate | 850/375 | 3.7/1.7 | 17.8/.0052 | 500/680 | High |

" | " | " | " | 600/816 | Ultra-High |

3-plate | 850/375 | 4.4/2.0 | 22.0/.0065 | 750/1020 | High |

" | " | " | " | 900/1224 | Ultra-High |

4-plate | 850/375 | 5.2/2.3 | 25.3/.0074 | 1000/1360 | High |

" | " | " | " | 1200/1632 | Ultra-High |

* Values listed are typical for release bearings with the recommended 38mm contact diameter. Larger contact diameters will increase release load.

** Weight and M.O.I. include pressure plate, carbon floater plates, carbon discs and steel hub, and may vary based on your particular spline.

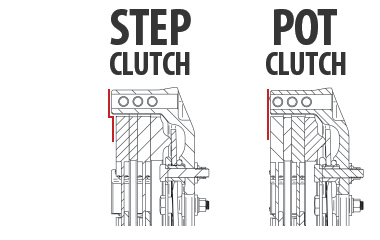

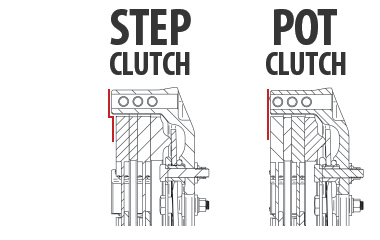

Tilton offers two different styles of every 5.5″ carbon clutch configuration: one designed to be compatible with a step-type flywheel, and another for pot-type (“no-step”) flywheels. Step flywheels have a .100″ step for contact with the friction material of the clutch, so clutches made for this application will have a .100″ height difference between the bottom friction disc and the end of the clutch cover legs (the mounting points). Pot flywheels don’t have this step, so the friction disc and clutch cover legs will be flush on clutches designed for them.

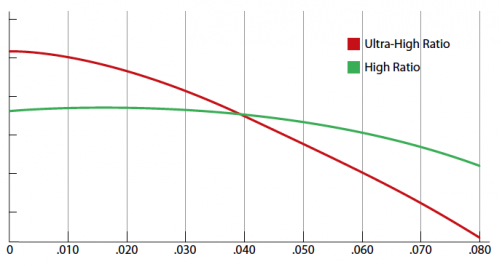

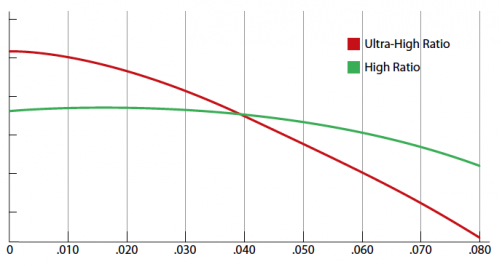

Tilton’s 5.5″ carbon racing clutches are available with either a High Ratio or an Ultra-High Ratio pressure plate. The standard High Ratio pressure plate offers high clamp load over a wide wear range, while the Ultra-High Ratio pressure plate provides 20% more clamp load and diaphragm spring travel (modulation). As seen on the graph below, the clamp load (or torque capacity) of the High Ratio pressure plate is relatively flat until .030″ (0.76mm) of wear; alternatively, Ultra-High Ratio pressure plates offer a higher initial clamp load at a faster wear rate.

- Standard pressure plate ratio for Tilton 5.5″ carbon clutches

- Short release travel for quick engagement and shifting

- Flat clamp load curve for longest wear range

- 20% more release travel than High Ratio for improved modulation

- 20% more clamp load than High Ratio for higher peak torque capacity

- Clamp load reduced more quickly with wear than High Ratio

P65 Notice

P65 Notice