| Disc Type | Diaphragm Spring Type | Torque Capacity | Release Load* |

|---|---|---|---|

| Sprung Hub Organic | G | 850 lb-ft | 600 lbs |

| Sprung Hub Organic | ORA | 650 lb-ft | 420 lbs |

| Solid Hub Cerametallic | G | 1250 lb-ft | 600 lbs |

| Solid Hub Cerametallic | ORA | 950 lb-ft | 420 lbs |

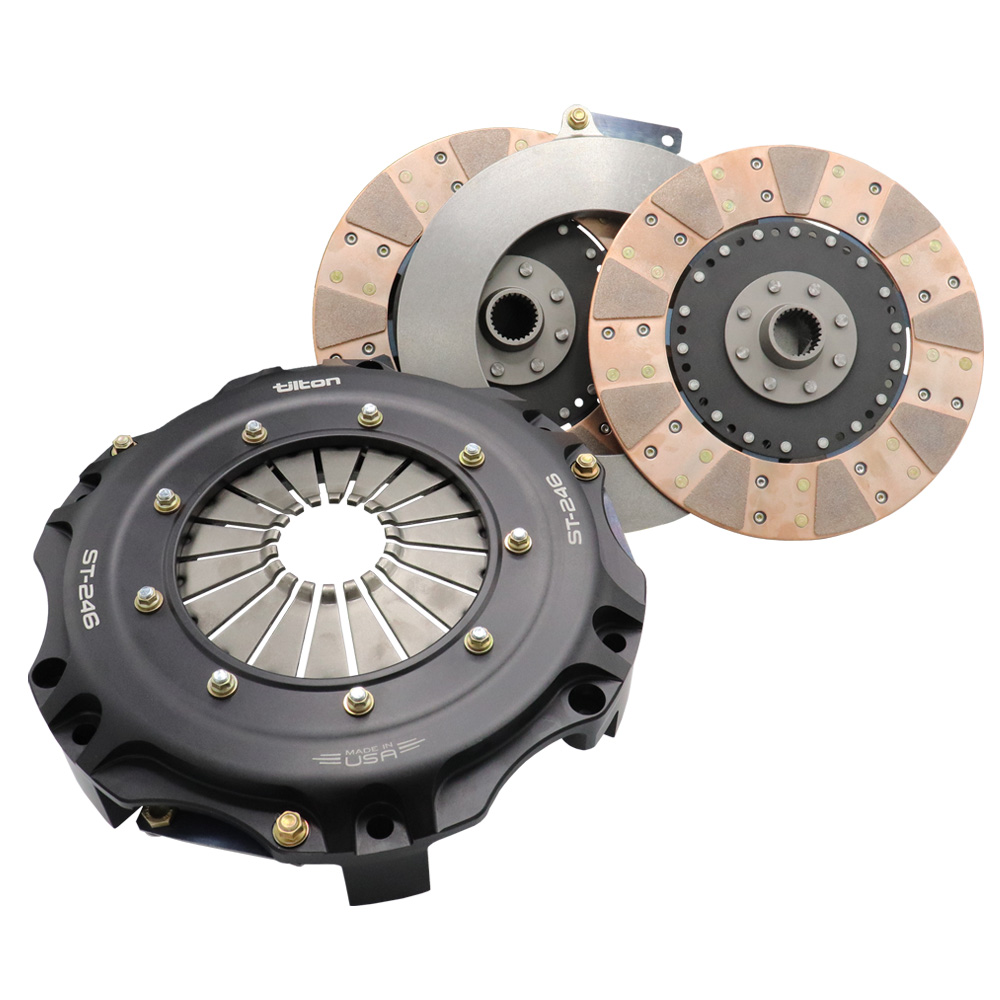

Since 1972, Tilton Engineering has been the leading supplier of small diameter racing clutches. Tilton racing clutches are world-renowned for their performance and reliability, winning championships in nearly every form of motorsport worldwide, including F1, NASCAR, IMSA, IndyCar, SCCA, Formula Drift, and SCORE.

Tilton has now applied their nearly 50 years of experience in racing clutches to develop the ST-246 line of twin-disc clutch kits for the high-performance street market. Unlike many of the “performance clutches” on the market, ST-246 clutches were designed from the ground up as a true performance twin-disc clutch and not an OEM-type stamped steel pressure plate with a floater added. Featuring an aluminum clutch cover that shares technology from Tilton’s championship-winning line of OT- Series racing clutches, ST-246 clutches feature heavy-duty straps that attach the pressure plate and floater plate to minimize noise. ST-246 clutches are available with either sprung-hub organic discs for street applications or solid-hub cerametallic discs for street/strip applications.

Precision machined aluminum clutch cover high-strength, stiffness and better balance than OE-type stamped steel covers.

High-mass main pressure plate and floater plate machined from the same proprietary materials as used by Tilton’s racing clutches, provides high heat capacity and resists warpage. Heavy duty straps attach plates to cover to minimize noise and provide clean clutch release.

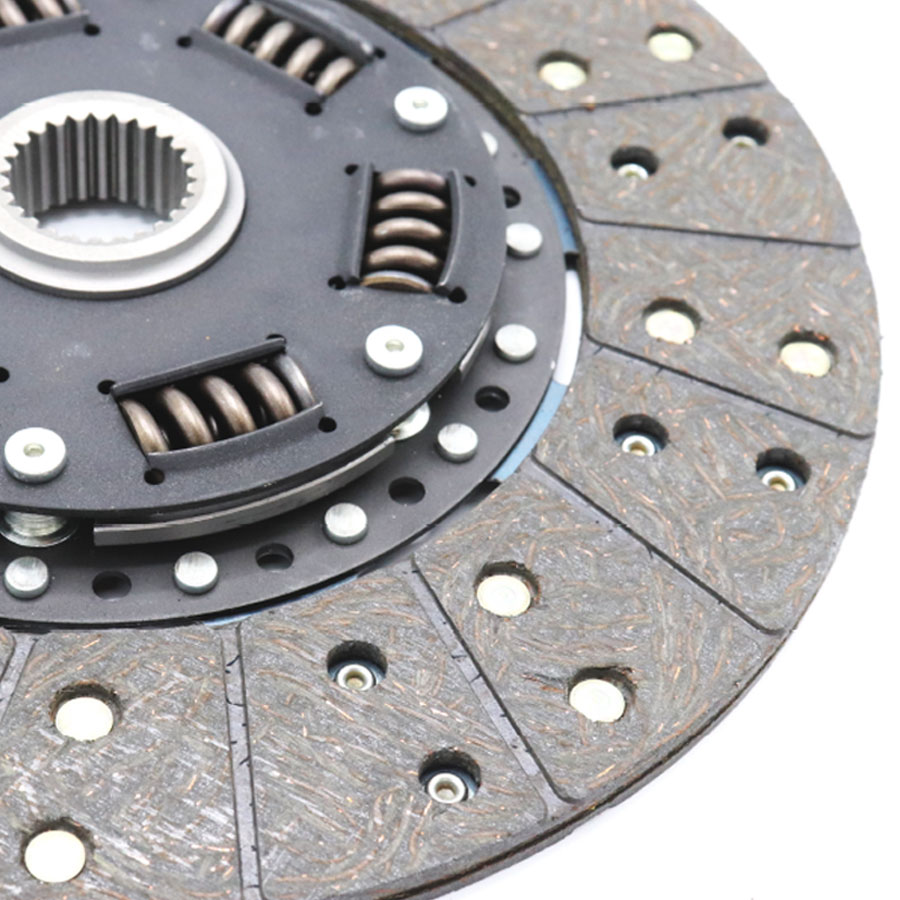

Organic disc option, with sprung center hub to dampen engine vibrations and reduce gearbox noise, provides smooth engagement for street use and holds 850 lb-ft of torque.

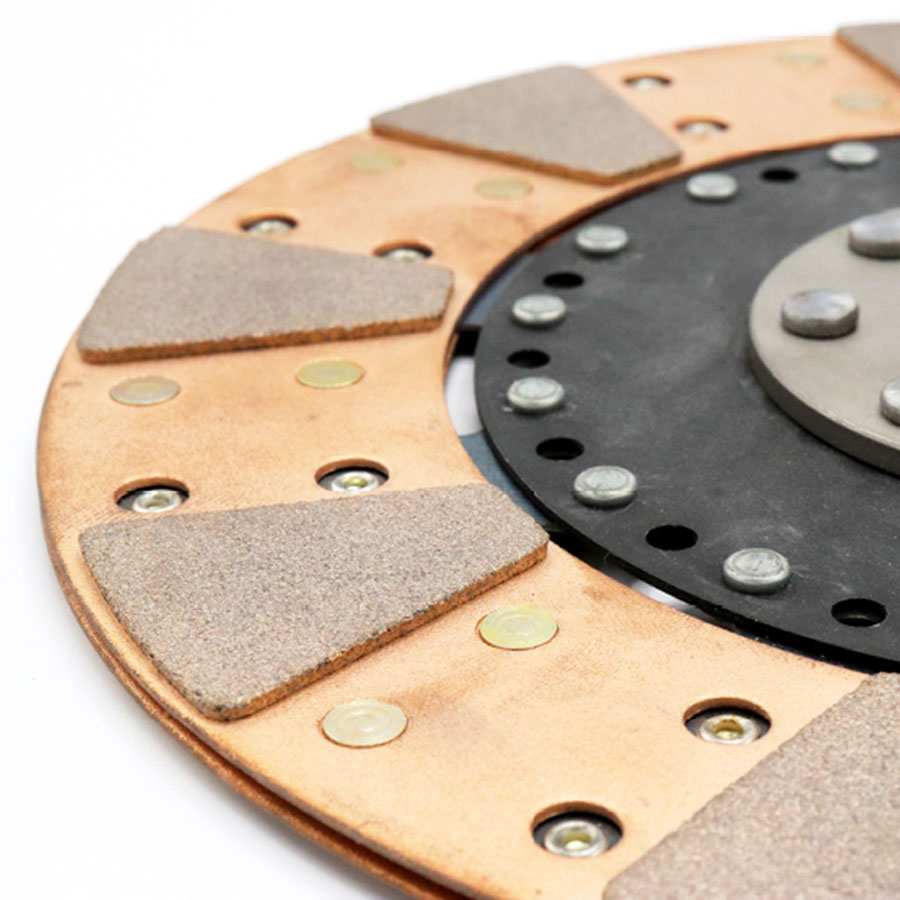

Cerametallic disc option, with solid center hub for higher strength, provides positive/precise engagement characteristics for streets/strip and holds 1250 lb-ft of torque.

P65 Notice

P65 Notice