Tilton’s 7.25″ OT-185 cerametallic racing clutches are primarily designed for racing applications where some clutch modulation is desired. They feature 4-paddle discs that incorporate a unique blend of ceramic and metallic materials. Cerametallic discs are thicker than sintered metallic discs, and they provide higher heat capacity through their increased mass. In addition, the engagement characteristics of cerametallic clutches are smoother than sintered metallic clutches. These features make Tilton’s 7.25″ OT-185 cerametallic racing clutches popular in the following applications:

- Rally

- Hill climb

- Road racing

- Club racing

- Off-road

- Extreme street/strip

Features

- Open, one-piece clutch cover design. Provides lower operating temperature, higher strength and minimized deflection for quick shifting.

- Five diaphragm spring rate options. Provides a wide range of torque capacities and release loads to tune the clutch for the application.

- Chrome vanadium diaphragm springs and an engineered pressure plate geometry. Provides a high clamp load-to-wear ratio, low release load and quick shifting.

- High-strength steel pressure and floater plates.

- .283″ thick friction disc. Provides excellent wear resistance and withstands elevated temperatures.

- Hardened steel thrust buttons provide a smooth and durable surface for pressure and floater plates.

- Dynamic spin balanced.

- Individually inspected for proper assembly and balance.

1-Plate specifications:

Weight**: 5.6 lbs/2.5 kg

M.O.I.**: 52.4 lb-in2/.0154 kg-m2

Spring Color | Torque Capacity

(lb-ft/Nm) | Release Load*

(lbs/daN) | Pressure Plate

(Ratio) |

White | 200/272 | 400/180 | High |

" | 240/326 | " | Ultra-High |

Buff | 240/326 | 480/211 | High |

" | 285/388 | " | Ultra-High |

Orange | 280/381 | 560/247 | High |

" | 335/456 | " | Ultra-High |

Gray | 340/462 | 680/299 | High |

" | 410/558 | " | Ultra-High |

Double Gray | 380/517 | 760/334 | High |

" | 455/619 | " | Ultra-High |

Triple Gray | 415/564 | 800/352 | High |

2-Plate specifications:

Weight**: 8.2lbs/3.7kg

M.O.I.**: 76.3lb-in2/.0225kg-m2

Spring Color | Torque Capacity

(lb-ft/Nm) | Release Load*

(lbs/daN) | Pressure Plate

(Ratio) |

White | 400/544 | 400/180 | High |

" | 480/652 | " | Ultra-High |

Buff | 480/652 | 480/211 | High |

" | 570/775 | " | Ultra-High |

Orange | 560/762 | 560/247 | High |

" | 670/911 | " | Ultra-High |

Gray | 680/925 | 680/299 | High |

" | 820/1115 | " | Ultra-High |

Double Gray | 760/1034 | 760/334 | High |

" | 910/1238 | " | Ultra-High |

Triple Gray | 830/1129 | 800/352 | High |

* Values listed are typical for release bearings with the recommended 44mm contact diameter. Larger contact diameters will increase release load.

** Weight and M.O.I. include pressure plate, carbon floater plates, carbon discs and steel hub, and may vary based on your particular spline.

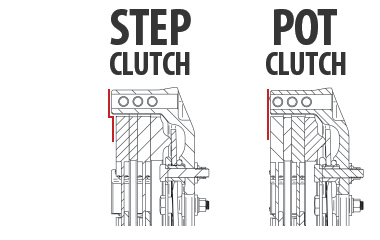

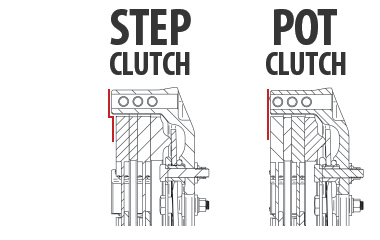

Tilton offers two different styles of every clutch configuration: one designed to be compatible with a step-type flywheel, and another for pot-type (“no-step”) flywheels. Step flywheels have a .100″ step for contact with the friction material of the clutch, so clutches made for this application will have a .100″ height difference between the bottom friction disc and the end of the clutch cover legs (the mounting points). Pot flywheels don’t have this step, so the friction disc and clutch cover legs will be flush on clutches designed for them.

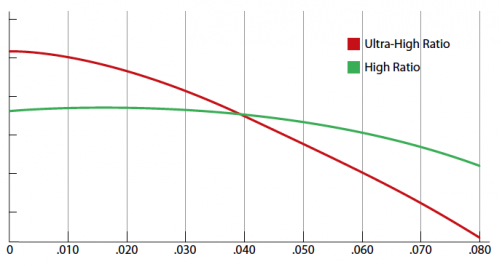

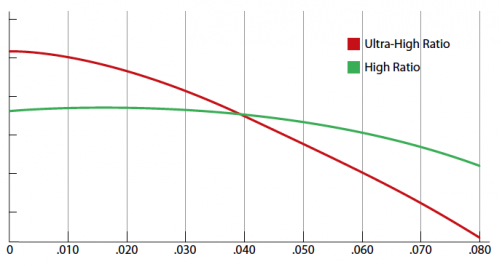

Tilton’s cerametallic clutches are available with either a High Ratio or Ultra-High Ratio pressure plate. High Ratio pressure plates offer high clamp load over a wide wear range, while Ultra-High Ratio pressure plates provide 20% more clamp load and diaphragm spring travel (modulation). As seen on the graph below, the clamp load (or torque capacity) of the High Ratio pressure plate is relatively flat until .030″ (0.76mm) of wear; Ultra-High Ratio pressure plates offer a higher initial clamp load at a faster wear rate.

- Standard pressure plate ratio for Tilton’s cerametallic clutches

- Short release travel for quick engagement and shifting

- Flat clamp load curve for longest wear range

- 20% more release travel than High Ratio for improved modulation

- 20% more clamp load than High Ratio for higher peak torque capacity

- Clamp load drops more quickly with wear than High Ratio

Tilton uses a color system for indicating the angle and weight of the clutch spring, which has an effect on release load and torque capacity for the clutch. The exact values for each color vary depending on the type of clutch, so be sure to check the Specs tab to find exact measurements.

P65 Notice

P65 Notice